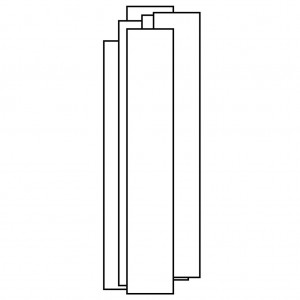

Starting with raw lumber, Koetje Wood Products begins the process of crafting each product. Lumber is chosen based on the customer’s specifications for species, grade and profile to be applied.

Each board is measured and cut down to specific lengths and specific angles to use the fewest boards and minimize waste.

Each board is measured and cut down to specific lengths and specific angles to use the fewest boards and minimize waste.

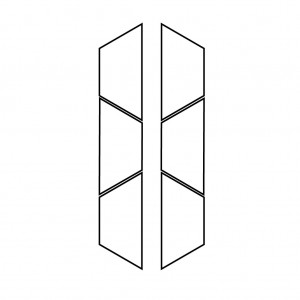

The angled boards are then finger jointed and glued/clamped together creating the rough form of the molding.

The angled boards are then finger jointed and glued/clamped together creating the rough form of the molding.

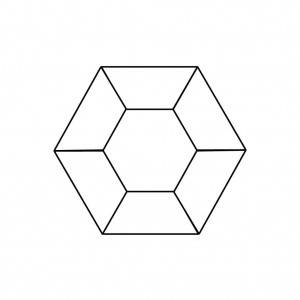

Once the glue has dried the molding is cut to the desired form with an allowance added for shaping and sanding.

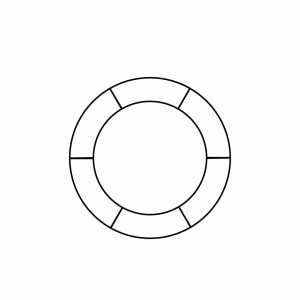

Once the glue has dried the molding is cut to the desired form with an allowance added for shaping and sanding. The moulding is then shaped with the desired profile and sanded by hand.

The moulding is then shaped with the desired profile and sanded by hand.